Field Operations

Reciprocating Compressor: Operations, Maintenance, Troubleshooting

Production Assurance - Troubleshooting

Offshore Fields Development - Pipeline & Flow Assurance

Liquefied Natural Gas (LNG)

Master Engine Care: Diesel Engine Maintenance Course

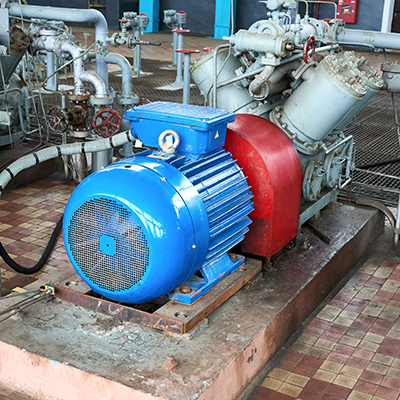

From generators, marine systems, and transport vehicles to construction equipment, diesel engines are used in various machinery. Even the most robust engines will break down without care, losing safety, time, and money. Our diesel engine maintenance course teaches students how to accurately diagnose, maintain, and repair diesel-powered systems and provides in-depth technical training with accuracy.

Here’s what your team will gain from this module.

- An understanding of basic engine systems, their components, and their functions.

- Guidance on preventative maintenance training best practices.

- Ability to troubleshoot common faults with diesel engines.

- Operation and maintenance training to perform oil analysis, fuel system servicing, and cooling system checks.

- Adherence to safety precautions when conducting inspection and repair procedures.

Unlike other courses, participants do not only learn from reading textbooks. They actively participate with real diesel engines, which helps build the confidence and skills needed to work effectively in stressful situations. Mastering diesel care skills aids productivity in maintaining marine vessels and managing logistics fleets.

Strengthen Field Operations with Targeted Maintenance Solutions

With operations dispersed among numerous locations, equipment startup failure can disrupt everything. This necessitates achieving field readiness using a systems approach. The diesel engine maintenance training is part of a broader strategy that consists of a well-defined, structured plan, rapid fault diagnosis, and effective asset management.

Why is our training approach effective?

- Technical skills for maintenance are integrated with principles from a maintenance planning course.

- Both corrective and preventive levels of maintenance are offered.

- SOPs for planned servicing and unplanned emergency repair workflows are crafted with the client’s teams.

- Field documentation, such as forms, guides, checklists, and related tools, is provided for immediate implementation.

From oil exploration offshore platforms to logistics containers, all organizations benefit from field workers who can troubleshoot, plan, optimize, and implement those plans. Our blended engine expertise, planning, and strategy approach achieves maximum value.

Build Your Team’s Confidence in Critical Field Skills

Technical skills are not enough in today’s fast-paced world. A technician must analyze a problem, make quick decisions, and simultaneously adhere to safety and operational protocols. Our diesel engine maintenance program refines critical thinking, effective communication, and mechanical skills.

Here’s how we create all-rounded professionals:

- We break down real-life scenarios for diagnosis so learners can gain confidence in their ability to evaluate the problem accurately.

- Learners practice intricate fault diagnosis communication between teams.

- We actively teach roleplay for teamwork in decision-making scenarios in the field.

- We scope and introduce new digital maintenance log tools that track data granularity.

- Learners graduate with the ability to perform basic tasks autonomously with minimal supervision or direction from planners, supervisors, or safety officers. Doing something over and over again and mastering it builds confidence.

Ensure Safety and Efficiency in Every Operational Step

A proficient safety culture is integrated into every company’s operations and is not just listed as one of the objectives. The same can be said for diesel engines, as one error may easily become disastrous. That is why our diesel engine maintenance planning course incorporates safety in every section. Each step taken from the moment a technician steps into a machine to the final walkthrough is pre-planned and incorporated within an engineered safety system.

We instruct your personnel to:

- Effectively adhere to lockout/tag-out requirements during engine maintenance activities.

- Use personal protective equipment appropriately and recognize danger signs.

- Know the combustion, exhaust exposure, and fuel system handling risks.

- Comply with safety regulations in harsh weather or isolated locations.

This appeal not only protects workers but greatly improves productivity. Poor procedures or accidents result in immeasurable downtime that compromises operations. Providing an embedded solution positively impacts the field and almost guarantees success. Teams are more motivated to perform their tasks because they can rest assured they will do it right the first time.

Partner with MTC Limited for Long-Term Success

Investing in professional training should guarantee positive returns years down the line, and at MTC Limited, we pride ourselves on offering more than just a one-off course. We are your ongoing partner in field excellence. Be it at the commencement or enhancement level, our diesel engine maintenance course and associated maintenance planning course modules will equip your team to handle any challenges that come their way.

What makes us unique:

- Our curriculum is developed around actual market requirements and the needs at a worksite.

- We employ instructors who are practitioners in oil & gas, marine, and heavy industry.

- Teaching is done via practicals and case studies instead of textbook approaches.

- Participants obtain industry certifications without the need to go through endless bureaucracy.

Skill enhancement is an objective that promotes entire teams rather than individuals. It is easier to carry out work when every technician delivers as expected and every planner thinks clearly. Field operations become smoother, faster, and safer.

FAQs

What is the RYA diesel engine maintenance course?

The RYA diesel engine maintenance course is a short program designed with practical components by the Royal Yachting Association (RYA). It aims to help operators and other stakeholders understand the principles of safe maintenance and troubleshooting of small diesel engines.

What qualifications do I need to be a maintenance planner?

To be a maintenance planner, candidates are usually required to have work experience in a technical or mechanical area, usually gained with a diploma or certificate in engineering, maintenance, or operations. Some maintenance work experience supplemented with training on scheduling, planning tools, and risk management practices is also useful.

What are the top 3 skills for a maintenance planner?

The top 3 skills for a maintenance planner are:

- Centralized and Time Management Capabilities: This is the skill to manage resources, time frames, and work orders effectively.

- Craftsmanship Background: Understanding machinery, parts, and how they break down gets you closer to making the right decisions when executing plans.

- Reporting: Working with site technicians, subcontractors, and supervisors, participating in communication with all parties involved.